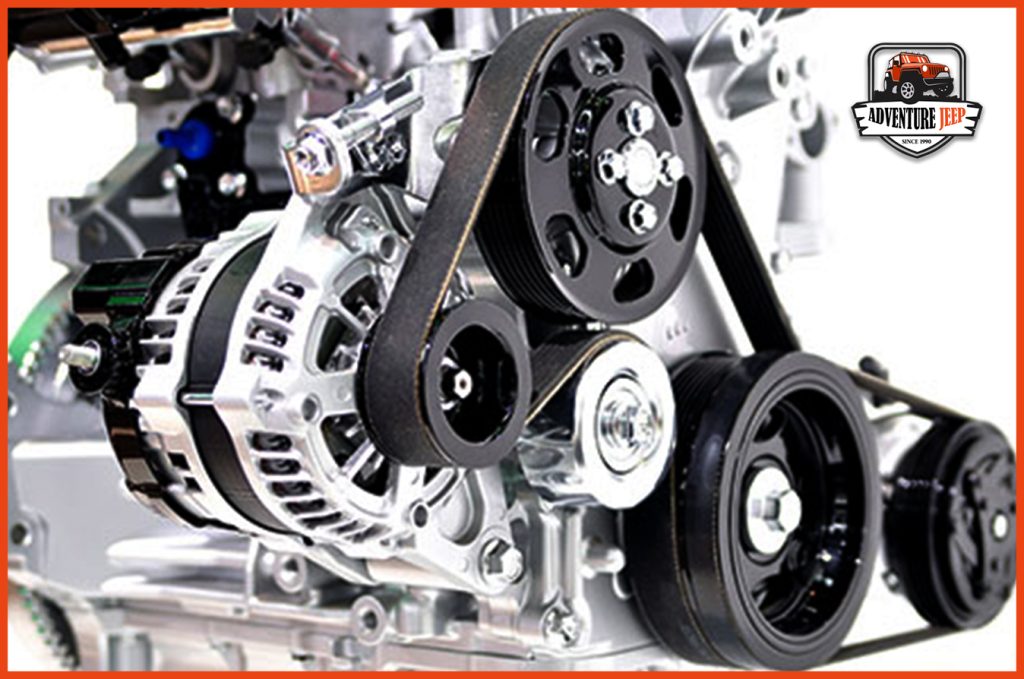

To stop a serpentine belt from slipping, ensure the belt tensioner is properly adjusted and the belt is in good condition. A serpentine belt is a crucial component of a vehicle’s engine as it drives multiple accessories such as the alternator, power steering pump, and air conditioning compressor.

However, a common issue that can arise is the serpentine belt slipping, which can result in a loss of power to these essential parts. To prevent this problem, it is important to ensure that the belt tensioner is properly adjusted.

This can be done by checking the manufacturer’s specifications and using a tensioner tool to tighten or loosen the tension. Additionally, regularly inspecting the belt for signs of wear or damage, such as cracks or fraying, is essential. By taking these preventative measures, you can effectively stop a serpentine belt from slipping and maintain the optimal functioning of your vehicle’s engine.

Regular Inspections And Maintenance

Regular inspections and maintenance are crucial for preventing a serpentine belt from slipping. To begin, check the condition of the belt regularly. Look for cracks, fraying, or any signs of wear. Next, ensure proper tensioner adjustment. The belt should have the right amount of tension, neither too loose nor too tight.

If adjustment is needed, follow the manufacturer’s guidelines. Lastly, check the pulley alignment. Misaligned pulleys can cause the belt to slip. Make sure all pulleys are aligned correctly and rotate smoothly. By following these steps, you can keep your serpentine belt from slipping and ensure optimal performance of your vehicle’s engine.

Remember, regular inspections and maintenance are key in preventing these issues and extending the life of your serpentine belt.

Proper Belt Installation Technique

A properly installed and tensioned serpentine belt is crucial to prevent slipping. When installing the belt, ensure it follows the correct path around the pulleys. The tension should be just right, neither too tight nor too loose. Use a belt dressing or conditioner to enhance grip and reduce slippage.

Always refer to the manufacturer’s guidelines for the specific tensioning procedures of your vehicle. By following these steps, you can effectively stop a serpentine belt from slipping and maintain the smooth operation of your engine. With proper installation and tensioning, you can avoid issues such as squeaking, loss of power, and potential damage to other engine components.

Take the time to correctly install and maintain your serpentine belt for optimal performance and longevity.

Replacing A Worn-Out Serpentine Belt

Replacing a worn-out serpentine belt is essential for preventing slipping and maintaining optimal vehicle performance. Follow these steps for a seamless replacement process. Start by locating the belt tensioner and using a suitable tool to release tension. Slide the old belt off the pulleys, taking note of the routing path.

Next, install the new OEM or high-quality replacement belt, ensuring it follows the original routing. Once properly installed, release the tensioner to secure the belt tension. Regularly inspecting and replacing the serpentine belt when it shows signs of wear or damage prevents potential issues down the line.

By using genuine or high-quality replacement belts, you ensure a reliable and lasting solution. Maintain the health of your vehicle’s serpentine belt for optimal performance and avoid slipping troubles.

Use Of Belt Dressing Or Conditioner

A serpentine belt slipping can be addressed by using a belt dressing or conditioner. Choosing the right product is crucial. It is recommended to opt for a high-quality belt dressing or conditioner that matches the specifications of your vehicle’s belt.

The application method and frequency should be followed as per the instructions provided by the manufacturer. It is essential to ensure that the belt is clean and free from debris before applying the dressing or conditioner. Regularly checking the tension and condition of the belt is advisable to prevent slipping and maintain optimal performance.

By using the appropriate product and taking proper care, you can effectively stop a serpentine belt from slipping and avoid potential damage to your vehicle’s engine.

Tensioner Replacement Or Adjustment

A faulty serpentine belt tensioner can cause the belt to slip, leading to a range of issues. Signs of a faulty tensioner can include squealing noises, difficulty in steering, and worn-out belts. To prevent slipping, the tensioner can be replaced or adjusted.

When replacing the tensioner, it is important to follow the proper procedure. Start by locating the tensioner and releasing tension from the belt. Next, remove the old tensioner and install the new one, ensuring it is properly aligned. Finally, reapply the tension to the belt by using the appropriate tool.

Regular inspection of the tensioner and belt is key to ensuring they are in good condition, thus preventing slipping and potential damage to other components in the engine.

Addressing Misaligned Pulleys

Regular pulley maintenance is crucial in preventing the slipping of a serpentine belt. By addressing misaligned pulleys, you can tackle this issue effectively. Identifying misalignment is the first step; once the problem is detected, it is important to correct it promptly.

Regular inspection and adjustment of pulleys can help maintain their alignment and prevent belt slippage. Neglecting this maintenance can lead to reduced belt performance and potential damage to the engine. Keeping pulleys aligned ensures smooth belt operation and maximizes the efficiency of various engine components.

By paying attention to this often overlooked aspect, you can prevent serpentine belt slipping and maintain the optimal functioning of your vehicle’s systems. Remember, a small investment in pulley maintenance goes a long way in avoiding costly repairs in the future.

Frequently Asked Questions On How To Stop A Serpentine Belt From Slipping

What To Do If Serpentine Belt Is Slipping?

If the serpentine belt is slipping, follow these steps: 1. Check the belt tension and adjust it if necessary. 2. Inspect the condition of the belt for any signs of wear or damage. 3. Look for any obstructions that may be causing the slippage and remove them.

4. If the problem persists, consider replacing the serpentine belt with a new one.

What Would Cause A Serpentine Belt To Slip Off?

The serpentine belt can slip off due to wear and tear, improper tension, or a faulty belt tensioner.

Can I Spray Wd 40 On My Serpentine Belt?

No, you should not spray WD 40 on your serpentine belt as it can cause damage.

How Can I Tighten My Serpentine Belt?

To tighten your serpentine belt, follow these steps:

1. Locate the tensioner pulley.

2. Using a wrench or socket, rotate the tensioner to release the tension on the belt.

3. Slide the belt off the pulleys.

4. Install the new belt, following the correct routing diagram.

5. Rotate the tensioner again to create tension on the belt.

6. Ensure the belt is properly aligned on all pulleys.

7. Double-check the tension and make any necessary adjustments.

8. Start the engine and check for proper belt operation.

Remember to consult your vehicle’s manual for specific instructions.

How Can I Tell If My Serpentine Belt Is Slipping?

If you hear a squealing noise, experience power steering issues, or notice flickering lights, your serpentine belt may be slipping.

Why Does A Serpentine Belt Slip?

A serpentine belt can slip due to excessive wear, a misaligned pulley, insufficient tension, or contamination with fluids like oil or coolant.

Can I Fix A Slipping Serpentine Belt Myself?

Yes, you can tighten the belt tension, align the pulleys, or replace a worn belt to fix a slipping serpentine belt, but it’s recommended to consult a professional mechanic.

Conclusion

To ensure that your serpentine belt doesn’t slip, regular maintenance and proper installation are key. By inspecting the belt for signs of wear, keeping it properly tensioned, and regularly checking the pulleys and belt alignment, you can prevent potential slipping issues.

Remember to consult your vehicle’s manual for specific instructions and torque specifications. Additionally, using belt lubricant or dressing can help improve traction and reduce the chances of slipping. If you are uncertain or uncomfortable with performing these tasks, it is always wise to consult a professional mechanic.

Taking the time to address serpentine belt slipping can save you from costly repairs and potential breakdowns on the road. Prioritizing belt maintenance will help keep your vehicle running smoothly and ensure your safety on the road.

Leave a Reply